Brief introduction of MX series Ball mill

MX series Ball mill, with the foreign advanced technology introduced by our company R&D department, is a kind of new type and high-efficient powder and superfine powder processing machinery, used for grinding the medium and low-hard material that Moh's hardness is below 9, humidity is less than 8%, and non-flammable non-explosive minerals, such as calcite, cretaceous, caoline, limestone, Fly ash, bentonite, talcum, mica, magnesite, illite, pyrophyllite, Malachite, vermiculite, sepiolite, Attapulgite clay, rectorite, diatomite, barite and so on. And also is an ideal ultra-fine grinding equipment for non-metallic ore materials at present. When the Moh's hardness of the material is between4-6, the wearing parts life will be increased.

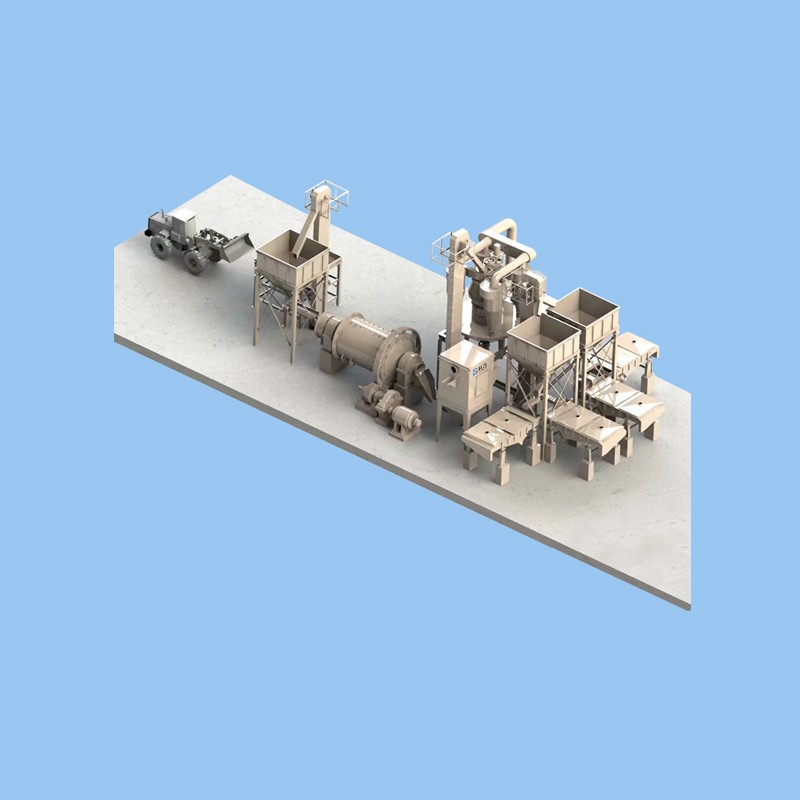

Characteristics of MX series super fine ball mill production line

1.The design is different from the traditional cement mill and mining and metallurgy mill etc, meets the requirement of Germany ultra-fine filler mineral processing.

2.Optimizing the major axis, to prevent excessive grinding, in order to achieve the best grinding result.

3.Optimizing the grid plate open porosity and hole opening design, improve the grinding fineness by using small grinding media.

4.The end discharging final product adopts grid plate, smoothly discharging material, without material fully fill the shell, no need to cool the shell.

5.The hard material adopts the non-iron contamination design, the liner and grinding media adopts alumina ceramic, quartz, SILEX or special material.

6.The grinding media should be added reasonably matching, high filling rate, high efficiency.

7.Adding additive when grinding ultra-fine powder, improve the grinding efficiency.

8.Optimizing the match of the drive and the grinding energy consumption, maximum save the energy.

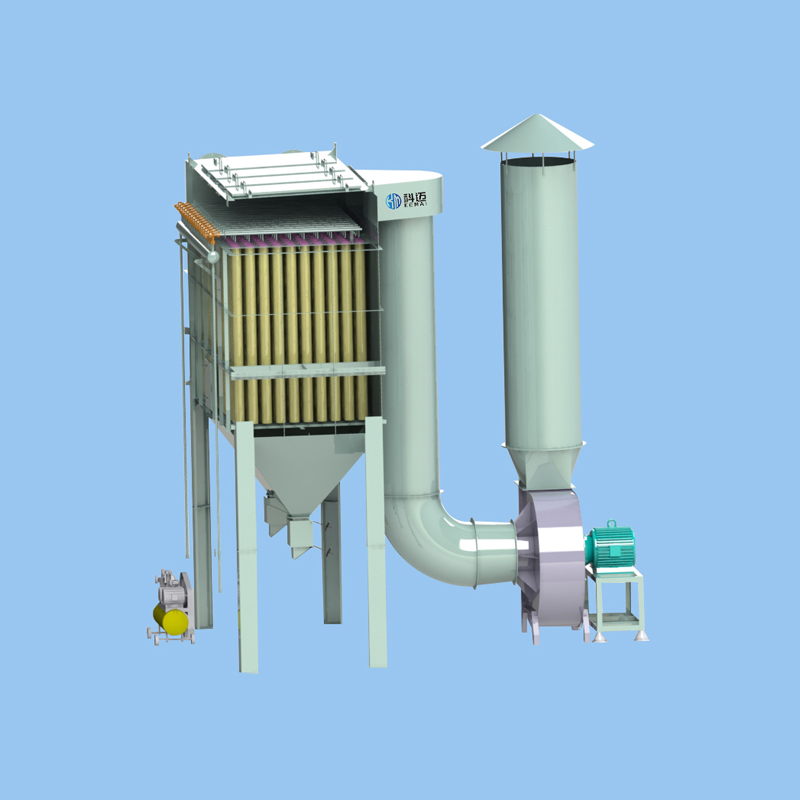

9.Forming a close system with the classifier, negative pressure conveying, no dust.

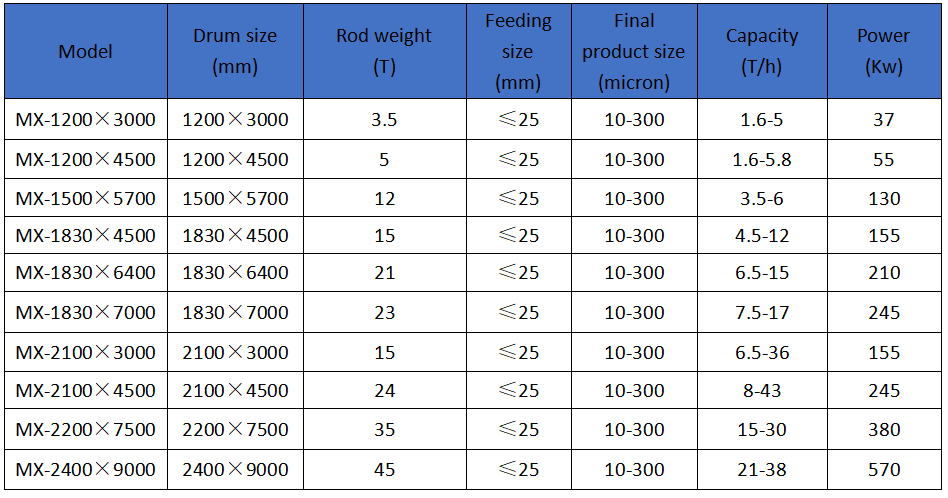

Technical parameters of MX series ball mill

Some of our product

Shandong Kemai machinery equipment co.,Ltd

Shandong Kemai machinery equipment co.,Ltd