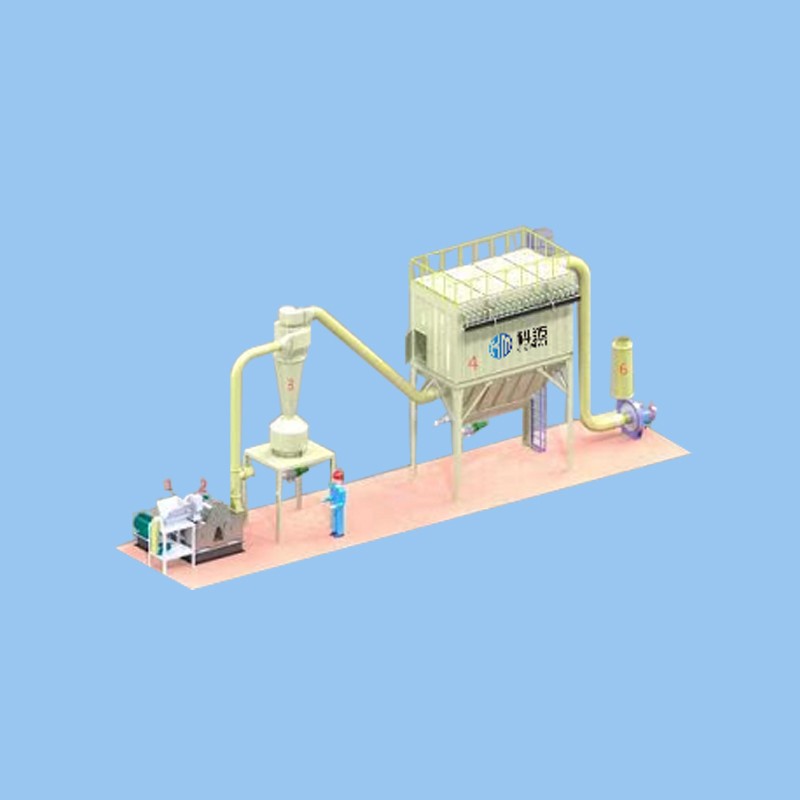

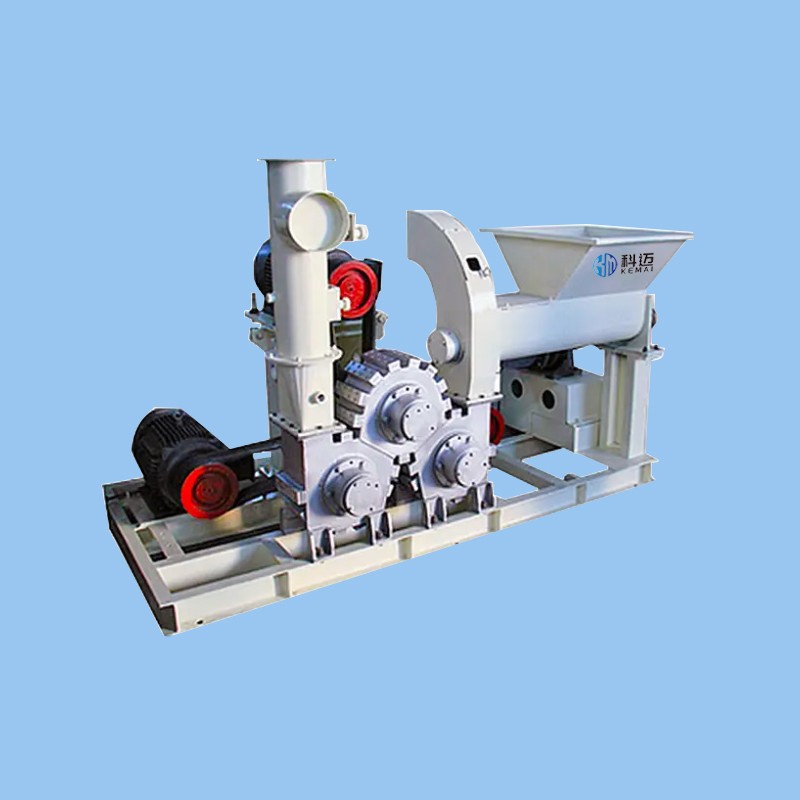

Introduction of CM series Powder coating machine

Powder surface modification (activation) has important practical significance to improve the performance of powder, increase its practical value and develop the development of application fields.Surface modification (activation) is one of the necessary processing methods for fillers to change from general fillers to functional fillers, and it is also the main purpose of surface modification of mineral fillers. The main effects of surface modification of mineral fillers include dispersion, viscosity reduction, filling and interface mechanics. The most commonly used modification methods are surface chemical modification, coating modification, and mechanistically modification.

Characteristics of CM series Powder coating machine

1.Continuous operation, large capacity, suitable for industrialization production in various scale.

2. High use and less consumption of modifying agent. high covering and active index of power,energy saving.

3.Both modifying and dispersion function, suitable for any fine materials, special active effect for material with small proportion and big cubage weight like white carbon, mica powder and talcum powder.

4.Powder and agent mixing and running in high speed and vortex, high modifying efficiency, with little change of granulate shape.

5.Running at vacuum, air tight, no dust leakage, no pollution, good operation condition, low labor intensity.

6.Operating in heat and cold conditions, no additional heating or cooling system required, easy operation.

7.Independent fluid and non-fluid agent adding system for continuous, stable and even operation.

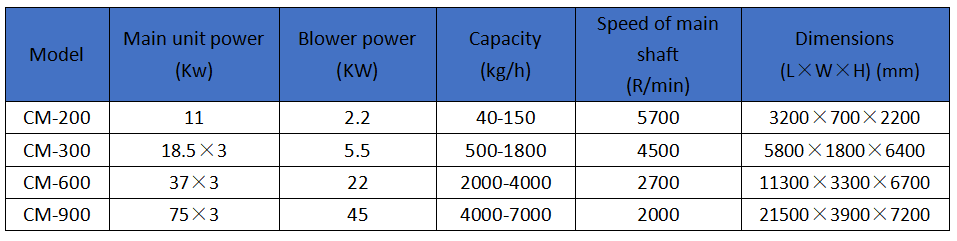

Technical parameters of CM series powder coating machine

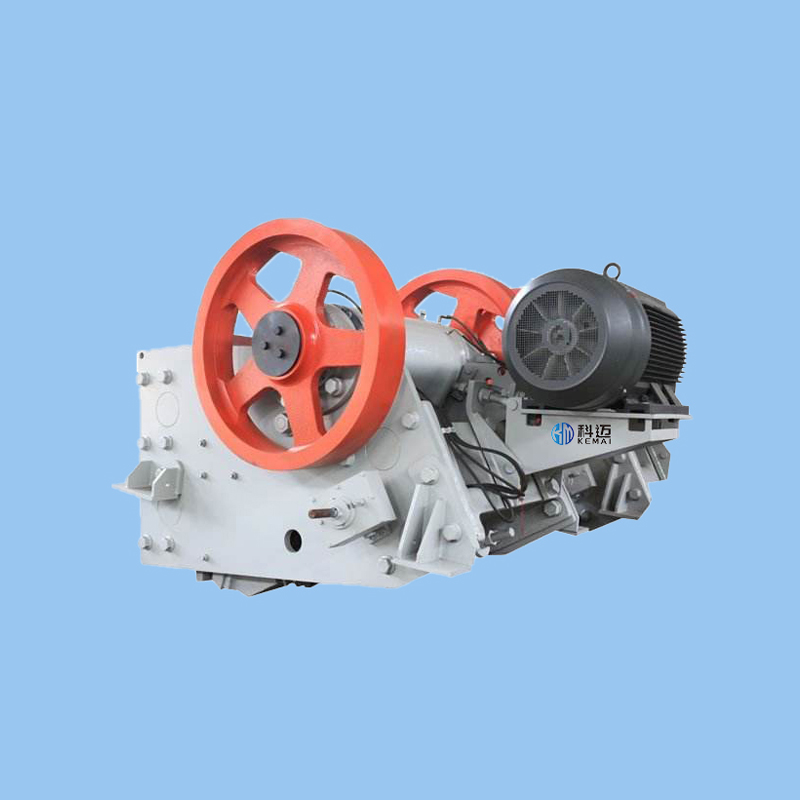

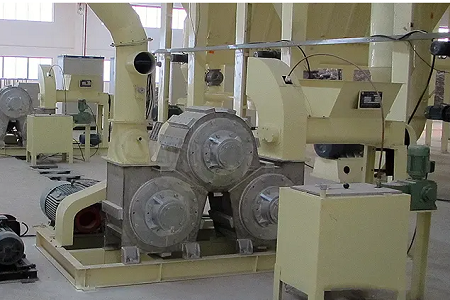

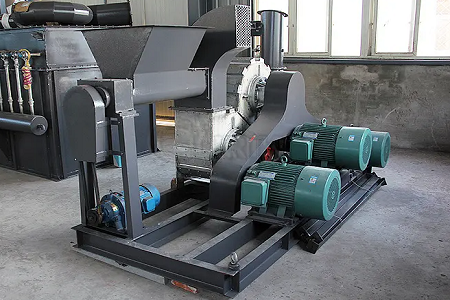

Some of our product

Shandong Kemai machinery equipment co.,Ltd

Shandong Kemai machinery equipment co.,Ltd